Technology upgrade of #beverage_carbonators, #blenders and other #beverage_carbonating_systems

We hold this truth to be self-evident, that if you bond on the molecular level CO2 and the liquid in the form of gas, then you receive the best physically feasible dissolution of gas in the liquid.

Politech-Plus does not only produce high-accuracy inline carbonation systems but upgrades beverage blending&carbonating equipment of any carbonated beverage filling line brand and model.

SubCarb is a patented technology designed to minimize both electricity and CO2 consumption, reduce long-term CAPEX needs, dramatically improve the quality of carbonation in the process, and improve the environmental impact. The upgrade project offers an exceptionally good ROI at the same time.

Our technology allows carbonating beverage and water at ultra-high temperatures of up to +23°C (+69°F) and lower carbonation pressures than any other systems could deliver in reality. This guarantees significant savings on electricity and CO2. The drink does not foam on the filling machine or foams significantly less. Soft-drinks are drastically more stable through consumption and shelf-life. The dissolution of CO2 at the molecular level allows obtaining very fine bubbles, which is an indirect indicator of the quality of carbonation. Needless to mention, that carbonated drink's taste is influenced by the dissolved CO2 content in the beverage. The consistent CO2 content of well-dissolved CO2 is an important sign of product quality, especially when the quality is the top priority.

How is this outstanding result achieved?

In all known technologies of CO2 dissolution such as Venturi, Vortex, any innovative spray/nozzle variants and etc. the liquid in a liquid-phase is mixed with CO2 in gas-phase. In the meantime, Politech-Plus ensures that gas - С02 is mixed with gas - gaseous beverage, thus ensuring bonding at the molecular level with the surface of mass transfer 10 000 - 12 000 times larger than the one in other technologies. The effectiveness of carbonation reaches its physically feasible maximum no matter whether you carbonate water, mineral water, soft drinks, cider, beer, energy drinks and etc.

Politech-Plus beverage carbonation technology is realized in a compact self-contained patented device, which is of modular design. There is no need to halt production. The unique straight-forward design of the device makes it maintenance free. The upgrade is easy and reliably performed on any beverage mixer, carbonator, blender, and any carbonating system you may possibly have or think of.

We have solid experience in upgrading Sidel Starblend, Mojonnier Carbocooler, KHS Innopro Paramix, Carbomix and DCX, Krones Contiflow, APV, Sacmi Blendomas, Famix, Matrix Promix, Ektam Megamix, Manzini Premix, Comac Premix, Орелпищемаш, Орелпродмаш, Ленпродмаш, Стальпромтехнологии, TMCI Padovan Blendtech Premix, AMS Ferrari Premix, Nate OSN, GEA Dicar-B, CFT/CBS Premix Carbonators, SIPA Massblend, and other beverage carbonation systems.

If you are looking to reduce energy bills (electricity and CO2), reduce CAPEX in the long run, improve the quality of carbonated soft-drinks, improve process safety and stability and decrease the negative impact on the environment, SubCarb is here to help.

Politech+ LAB is a deep science division of Politech-Plus, which uses advanced experimental techniques, fundamental science, and big data simulations to further improve the practical applications of the carbonation technology.

Gear up your CSD filling line with the world's most powerful carbonation technology!

Преимущества технологии газирования напитков от Politech+

Beverage Carbonation Technology from Politech+

up to 97%

process carbonation efficiency

10 000 times

LARGER

surface of mass transfer

in comparison to other technologies

7 main problems of soft drinks carbonation

Politech+ excitingly solves

1.

Water/drink requires cooling before carbonation

2.

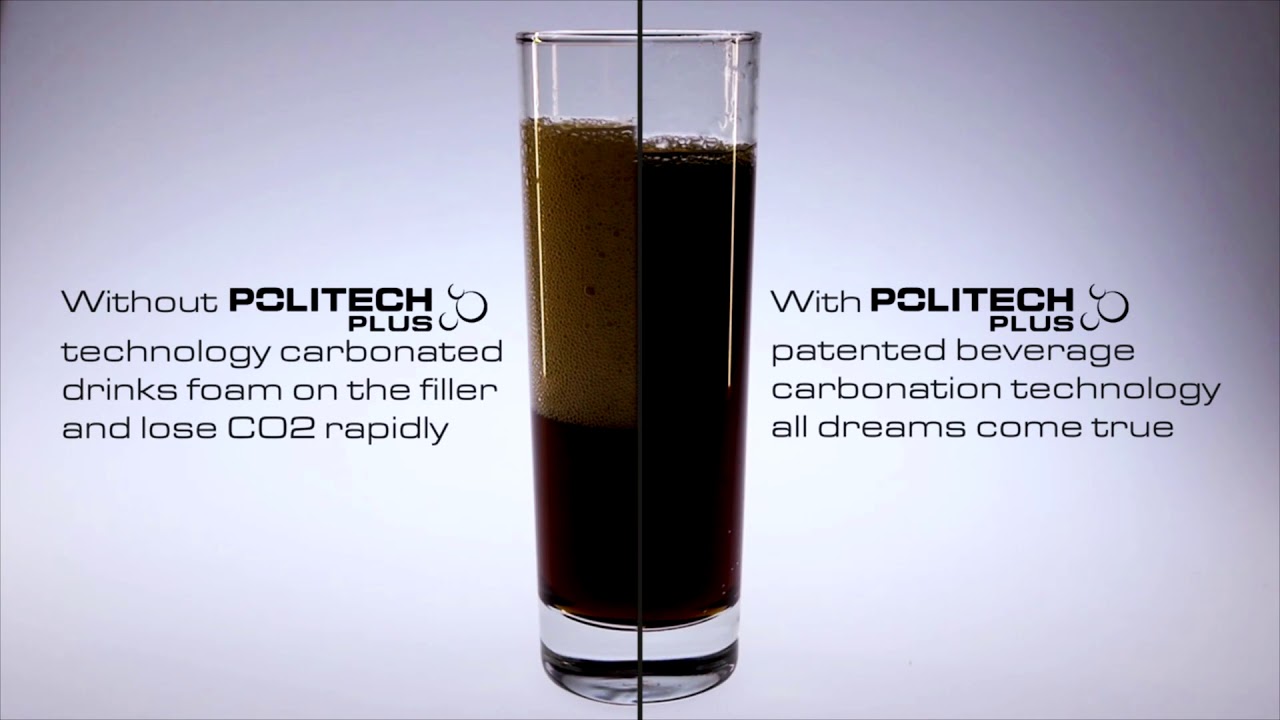

Product losses occur due to foaming. Reduced filling line speed = low OEE

3.

СО2 effectiveness is unsatisfactory. C02 Yield is low.

4.

Low CO2 carbonation quality, large bubbles, litt;le fizziness

5.

CO2 gathers at the neck of the bottle and is not retained well

6.

Energy is spent on heating cans in a heat tunnel, and then on drying

7.

High energy costs are required on drying glass bottles

Benefits of #continuous_beverage_carbonating system upgrade

Energy savings:

CO2

Electricity

Get the required level carbonation quality without cooling

CO2 bounding at the molecular level allows obtaining the required level of well-bounded CO2, for example 8,4 g/l or 4,2 v/v % at high and ultra-high temperatures and in many cases lower carbonation pressures.

This means significant electricity and CO2 savings which result in the fast payback period of the upgrade of the technology.

Carbonation is physically perfect and greatly enhanced even at an ambient temperature of the drink to be carbonated – up to +20°C (+68 Fahrenheit).

Turn off “air knives” when the glass bottles are filled at ambient temperature as there will be no or little condensate. In addition, save on electricity and compressed air and forget about labeling problems.

Foaming

Reduction

Reduce excessive foaming or eliminate it completely on the filling machine

CO2 bonding at the molecular level stands not only for less electricity consumption but for less foaming on the filling machine.

The reduction of foaming 2-2,5 times or complete elimination leads to savings of syrup and better retention of CO2. The savings on product loss due to foaming support the payback period of the upgrade in many cases on its own if foaming is a major issue. The OEE of the filling line improves as well as.

Enhance

Quality

Stay ahead of your competitors with an unmatchable quality of carbonation

When the product quality is a top priority, it is important to ensure that the carbonated beverage stays actually carbonated after the bottle is opened. Some clients observe, that carbonation is retained better over time than before the upgrade.

Politech+ technology offers unmatchable residual CO2 concentration and stability of CO2 dissolved. The carbonation retention is greatly enhanced, as well as the likability of the fizzy drink by the consumer.

Companies that use Politech+ technology of molecular carbonation